- BY Kumi Hendrix

- POSTED IN Electrical Safety

- WITH 0 COMMENTS

- PERMALINK

- STANDARD POST TYPE

Is your home’s electrical system showing warning signs like frequent circuit breaker trips, buzzing sounds, or flickering lights? These could signal an outdated switchboard struggling with modern appliances’ demands, posing fire risks and safety hazards. In this guide, discover the top 7 signs your switchboard needs an upgrade, including absent RCDs and ceramic fuses. Learn how upgrading enhances home safety, complies with Australian standards, and requires a licensed electrician for peace of mind.

What is a Switchboard Upgrade?

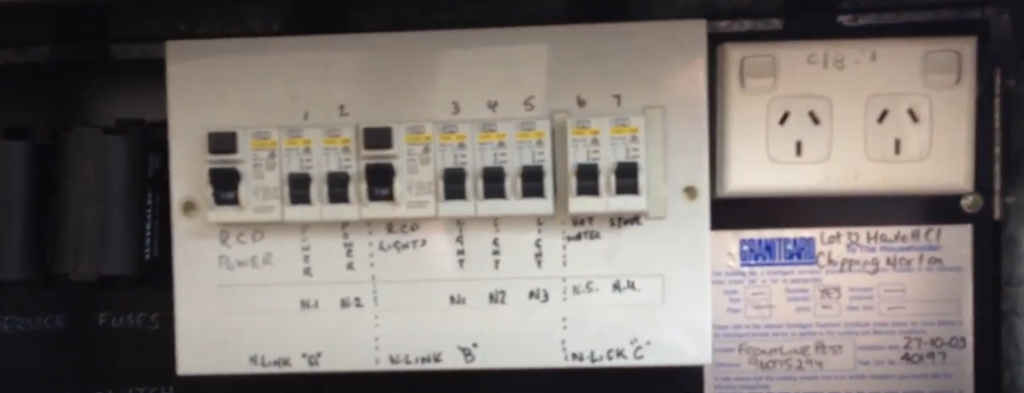

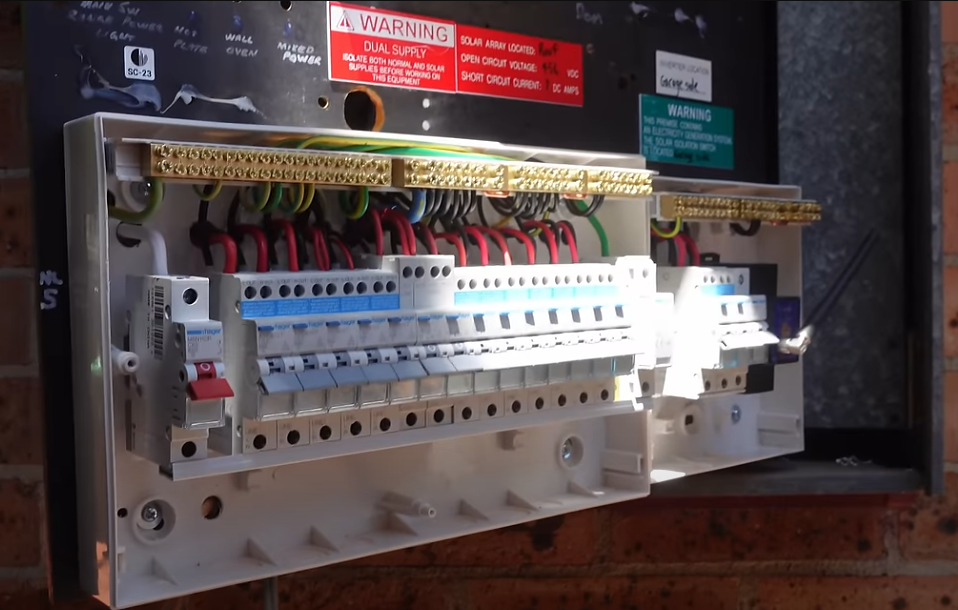

Upgrading a switchboard entails the replacement of obsolete electrical panels with contemporary systems that incorporate circuit breakers and residual current devices (RCDs). This process is essential for accommodating the elevated power demands of modern appliances while ensuring full compliance with Australian standards, including AS/NZS 3000:2018.

Definition of an Electrical Switchboard

The electrical switchboard functions as the central distribution point within a residential wiring system, channeling electrical power from the primary supply to individual circuits while incorporating protective mechanisms, such as fuses or circuit breakers, to mitigate overload risks.

In overseeing power distribution, the switchboard receives incoming electricity and directs it to essential components including lighting fixtures, power outlets, and household appliances through dedicated circuits. These circuits are rated between 10 and 32 amperes in accordance with the AS/NZS 3000:2018 standards.

To ensure seamless integration with existing home wiring, installation must be performed by a qualified licensed electrician. The switchboard should be compatible with prevailing cable types, such as copper or aluminum, and is generally designed to accommodate a main supply of up to 100 amperes.

Contemporary switchboard configurations incorporate Residual Current Devices (RCDs) to safeguard against electrical shocks. These devices automatically interrupt the circuit upon detecting a leakage current as low as 30 milliamperes.

Additionally, the switchboard addresses voltage surges generated by high-demand appliances, such as air conditioning units, through the inclusion of surge protection devices rated at 40 kiloamperes.

For optimal safety and compliance, the AS/NZS 3000:2018 standards require clear labeling of all components and mandate annual professional inspections.

This system can be illustrated via a straightforward schematic diagram depicting the main power feed connecting to circuit breakers and RCD branches.

Key Components Requiring Modernization

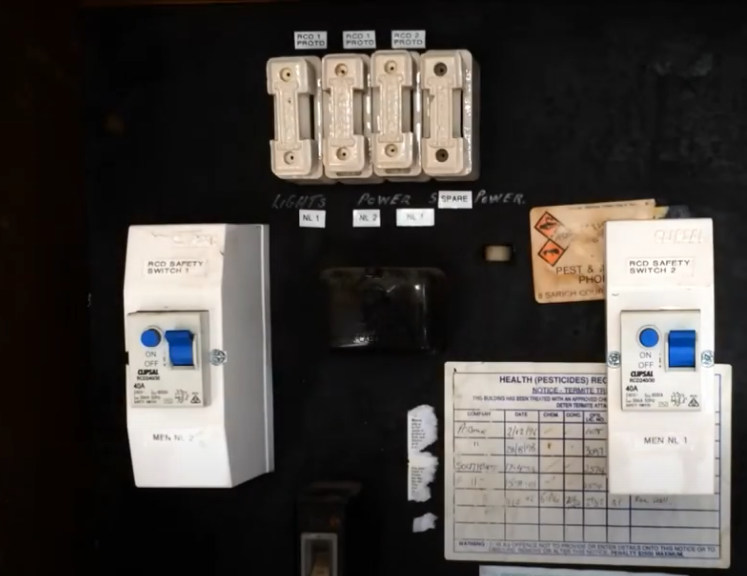

Obsolete components, such as ceramic fuses and the absence of residual current devices (RCDs) in legacy switchboards, do not meet contemporary safety standards. Accordingly, upgrades to circuit breakers and RCDs are required to provide superior protection.

The primary recommended upgrades are as follows:

- Replacement of ceramic fuses with circuit breakers: Substitute manual-reset fuses with automatic-tripping circuit breakers, such as those manufactured by ABB or Schneider Electric, to mitigate the risk of overload-induced fires. According to AS/NZS 61439, this upgrade delivers dependable short-circuit protection rated up to 50kA.

- Installation of RCDs in place of absent safety switches: Incorporate Type AC or Type B RCDs (for example, Hager 30mA models) to detect earth faults within milliseconds, thereby reducing the risk of electric shock by 90%, as specified in Australian standards.

- Addressing buzzing components through wiring enhancements: Upgrade wiring with low-humidity insulated cables to eliminate noise and thermal accumulation, thereby enhancing operational efficiency and service life.

- Integration of surge protectors: Employ metal oxide varistor (MOV)-based devices to protect against voltage surges, ensuring adherence to AS/NZS 61439 and promoting greater durability of electrical equipment.

- Implementation of arc fault detection: Deploy arc fault circuit interrupters (AFCIs) to promptly identify hazardous arcs, which can reduce fire incidents by 70%, according to research findings from the National Fire Protection Association (NFPA).

These measures, which generally entail costs between $500 and $2,000, significantly improve regulatory compliance and overall safety.

Primary Signs Indicating an Outdated Switchboard

Homeowners are advised to remain vigilant for key indicators of potential electrical issues, including recurrent circuit breaker trips, odors of burning insulation, and the presence of ceramic fuses. These warning signs typically denote an outdated switchboard that is inadequately equipped to handle modern power requirements, thereby introducing significant electrical hazards.

Sign 1: Frequent Overloading and Circuit Breaker Trips

Frequent electrical overloading arises when multiple contemporary appliances exceed the capacity of an outdated switchboard, resulting in repeated tripping of circuit breakers as a protective mechanism.

A typical illustration involves the concurrent operation of air conditioners and electric vehicle (EV) charging stations, which may demand 30 to 50 amps on a standard 20-amp circuit, thereby activating the breakers to avert potential damage.

To mitigate this issue, it is advisable to upgrade to higher-capacity breakers, such as 40-amp models, following a comprehensive assessment by a licensed electrician of the switchboard’s total load and wiring condition. Such upgrades generally incur costs ranging from $500 to $1,500 and require 4 to 6 hours to complete.

The Electrical Safety Office cautions against the grave fire hazards associated with overloads, noting that Australian fire data indicates 20% of residential fires stem from electrical malfunctions (Australian Institute for Disaster Resilience, 2022).

It is imperative to arrange a professional inspection prior to undertaking any modifications.

Sign 2: Persistent Tripping of Fuses

Persistent fuse tripping in older electrical systems, which typically employ ceramic fuses, signifies inadequate capacity to accommodate current loads, resulting in frequent power interruptions.

This issue frequently manifests during periods of peak evening consumption, such as when several high-demand appliances-including air conditioners and ovens-operate concurrently. This overload causes ceramic fuses, rated at 10-15 amps, to blow repeatedly.

For example, a household equipped with outdated wiring may encounter blackouts every evening around 7:00 PM.

To rectify this, it is advisable to upgrade to resettable circuit breakers as part of a panel replacement. These devices automatically reset following a trip and can safely manage loads of up to 20-30 amps.

According to the AS/NZS 3000:2018 standards issued by Standards Australia, persistent fuse tripping indicates non-compliance with electrical regulations and poses a risk of overheating.

Notably, a 2019 residential fire in Sydney, as investigated by Fire and Rescue NSW, was attributed to disregarded fuse trips, emphasizing the critical importance of conducting professional electrical audits.

Sign 3: Burning Smells from the Switchboard Area

A burning smell originating from the switchboard area indicates overheating wires or components, serving as a critical warning of potential electrical fire hazards in legacy electrical systems. This acrid, plastic-like odor may occur during periods of high electrical demand, such as evening peak usage, when appliances place significant loads on deteriorated wiring. Such alerts typically arise from insulation degradation or loose connections in switchboards exceeding 20 years in age.

- Respond promptly: Evacuate the premises to mitigate risks, and, if it can be done safely, disconnect power at the main breaker.

- Engage a licensed electrician for an immediate inspection, as any delay may intensify the hazards.

Research from the Queensland Fire Service reveals that burning odors are a precursor to 15% of electrical fires, emphasizing the importance of timely upgrades, such as installing modern circuit breakers, to bolster safety and avert substantial damages.

Sign 4: Buzzing or Humming Sounds

Buzzing or humming noises emanating from the switchboard are frequently indicative of loose connections or arcing within aging electrical wiring, which can compromise the overall integrity of the system.

A prevalent auditory indicator is a persistent hum that occurs under electrical load, such as when household appliances are in operation, signaling potential overheating. For example, this noise may become more pronounced during periods of high usage, such as evenings when multiple devices are active.

To rectify such issues, it is advisable to engage a licensed electrician like Diablo Electrical in Croydon Park to conduct professional rewiring as part of a comprehensive system upgrade. This process typically includes a thorough inspection of connections and the replacement of obsolete components.

According to the AS/NZS 3000:2018 standard, such noises serve as critical fault indicators, necessitating prompt action to mitigate associated hazards.

A case study from Brisbane in 2022 illustrates the risks involved: in a residential setting, persistent buzzing that was initially overlooked resulted in the melting of insulation within the switchboard, nearly causing a fire. Disaster was averted only through timely professional intervention.

Sign 5: Presence of Ceramic Fuses

The presence of ceramic fuses, a characteristic feature of switchboards predating the 1980s, signifies an outdated electrical system that lacks contemporary resettable protective mechanisms.

These fuses are visually identifiable as compact, cylindrical components made of porcelain or ceramic, typically measuring 1 to 2 inches in length, containing visible metal wire filaments and mounted on porcelain bases. In contrast to modern circuit breakers, ceramic fuses must be replaced after a single activation, which elevates the potential for fire hazards.

Per the Electrical Safety Office, ceramic fuses account for approximately 30% of failures in obsolete electrical panels, with more than 5,000 incidents reported annually in the United States (ESO Report, 2022).

For modernization, it is recommended to engage a licensed electrician to replace these fuses with miniature circuit breakers (MCBs), such as those manufactured by Siemens or Square D, which feature automatic reset capabilities and comprehensive overload protection. This upgrade generally incurs costs ranging from $500 to $1,500 and improves safety by up to 70%, in accordance with National Fire Protection Association (NFPA) standards.

Sign 6: Absence of Safety Switches or RCDs

The absence of safety switches or residual current devices (RCDs) in a switchboard indicates a lack of protection against earth leakage faults, which is a required feature in contemporary Australian residences.

This deficiency poses substantial risks, including the potential for electrocution in moist environments. For example, should an individual come into contact with a malfunctioning appliance in proximity to water-such as a bathroom light fixture leaking into a shower-the circuit may fail to trip, permitting a potentially fatal current to pass through the body.

To address this hazard, it is advisable to upgrade the switchboard by incorporating RCDs, which are designed to detect electrical imbalances and interrupt power supply within milliseconds. According to the Australian/New Zealand Standard AS/NZS 3000:2018, RCDs are mandatory for all new electrical installations and significant renovations.

Research conducted by Work Health and Safety Queensland demonstrates that RCDs avert approximately 70% of electrical electrocutions, thereby markedly improving residential safety. It is recommended to engage a licensed electrician to ensure full compliance with relevant regulations.

Sign 7: Flickering Lights and Power Fluctuations

Flickering lights and power fluctuations are typically caused by voltage instability in overloaded electrical circuits, a condition often aggravated by high-demand devices such as solar inverters.

Common manifestations of this issue include the dimming of lights when high-power appliances, such as air conditioners or electric vehicle (EV) chargers, activate, which indicates an uneven distribution of electrical load. For example, initiating operation of a microwave may result in bulb flickering due to abrupt voltage drops.

To mitigate these problems, it is advisable to upgrade to balanced circuits by redistributing loads across phases during electrical panel installation. Engage a licensed electrician to conduct a thorough assessment and perform the necessary rewiring, with typical costs ranging from $500 to $2,000.

According to a 2023 study by the Electric Power Research Institute (EPRI), EV charging in older homes can increase voltage fluctuations by 25%, emphasizing the importance of implementing modern subpanels or intelligent load balancers-such as those offered by Schneider Electric-to achieve effective voltage stabilization.

How Do Modern Appliances Contribute to These Signs?

Contemporary appliances, such as air conditioners, electric vehicle chargers, and solar panels integrated with battery storage, require substantially higher electrical power consumption. This elevated demand can overburden outdated switchboards, thereby intensifying common indicators of electrical strain, including circuit breaker trips and light flickers.

Increased Power Usage Demands on Older Systems

Older switchboards, engineered for low-wattage loads, often prove inadequate for contemporary appliances that generate surges of up to 5 kW, resulting in recurrent overloads and heightened safety hazards.

According to the Australian Energy Market Operator, electricity consumption in modern Australian households has increased by approximately 30% owing to energy-intensive devices such as air conditioners and electric vehicle chargers. For instance, a family in Queensland equipped with rooftop solar panels may experience frequent tripping of their 20-year-old switchboard during peak summer demand, exposing them to fire risks from 5 kW surges originating from inverters.

The repercussions encompass annual repair expenses exceeding $500, alongside elevated insurance premiums, as reported by the Clean Energy Council. Upgrading to a compliant Type B switchboard in accordance with AS/NZS 3000 standards entails an investment of $1,500 to $3,000, yet it delivers a return on investment within 2 to 3 years through annual savings of $200 on maintenance and reduced insurance costs.

It is advisable to engage a licensed electrician for a complimentary audit to evaluate the condition of your electrical setup.

Why Ignore These Signs? Common Risks of Delaying Upgrade

Disregarding indicators of an obsolete electrical switchboard exacerbates potential hazards, such as fires caused by overloading, electrocution resulting from faults, and power outages during periods of peak demand, thereby compromising the safety of homes and their occupants.

Overloading Leading to Electrical Fires

Circuit overloading exceeds the capacity of electrical systems, resulting in wire overheating and ignition. Burning odors frequently indicate the onset of potentially catastrophic electrical fires.

A notable incident occurred in the 2022 Sydney house fire, where overloaded circuits from multiple appliances caused insulation to ignite, leading to the displacement of a family (as reported by Fire Services Australia). Statistics indicate that electrical faults account for approximately 40% of residential fires in Australia each year.

To prevent such occurrences, adhere to the following recommended procedures:

- Map your home’s electrical circuits using an inexpensive circuit tester (approximately $20) to determine load capacities (typically 15-20 amps).

- Install arc-fault circuit interrupters (AFCIs, priced at $30-50 each), which detect arcing faults and automatically interrupt power supply.

- Redistribute electrical loads by disconnecting high-consumption devices, such as space heaters, from shared outlets and utilizing dedicated circuits where possible.

- Arrange for annual inspections by qualified electricians to ensure compliance with AS/NZS 3000 standards.

These preventive actions can reduce the associated risks by up to 70%.

Electrocution Hazards from Faulty Components

Faulty components within outdated switchboards present significant risks of electrocution to users, particularly in the absence of Residual Current Devices (RCDs) that interrupt power during earth faults.

A typical hazardous situation arises from inadvertent contact with a wet electrical appliance, such as a plugged-in toaster positioned near a sink, where water establishes an unintended conductive path to ground, resulting in an electric shock.

To address this risk, it is recommended to incorporate Residual Current Devices (RCDs) into the switchboard configuration. These devices are designed to monitor imbalances in electrical current flow and respond by tripping the circuit in mere milliseconds if leakage current surpasses 30mA.

According to the AS/NZS 3000:2018 standard, RCDs are required in residential installations across Australia and New Zealand for socket-outlets and areas posing heightened risks. Reports from the Electrical Safety Office indicate that these devices can reduce electrocution incidents by as much as 90%.

For professional installation, engage a licensed electrician to retrofit Type A or Type B RCDs, with associated costs typically ranging from $200 to $500. This ensures adherence to regulatory standards and facilitates ongoing safety verification through periodic inspections.

System Failures During Peak Usage

During periods of high electrical demand, such as summer evenings when air conditioning and lighting are in heavy use, outdated electrical systems are prone to failure. This can result in power outages and potential damage to appliances.

To mitigate these risks, begin by evaluating the capacity of your electrical panel; residences more than 20 years old often feature undersized breakers.

A recent incident in Brisbane illustrates this vulnerability: an overloaded switchboard tripped during a heatwave, leaving a family without electricity for several hours. According to Energy Safety Queensland, outdated switchboards experience a 25% failure rate under peak load conditions.

A recommended solution is to engage a licensed electrician to upgrade to a modern 100-amp panel equipped with surge protection. This enhancement typically costs between $1,500 and $3,000.

For added reliability, incorporate a generator inlet, such as the Reliance Controls 30-amp model, which costs approximately $200 and facilitates a seamless transition to backup power. Studies in Queensland indicate that such configurations can reduce outage risks by up to 80%.

What Are the Safety Benefits of a Switchboard Upgrade?

Upgrading the electrical switchboard represents a critical investment in home safety, as it integrates advanced protective mechanisms designed to mitigate fire hazards and deliver dependable power distribution. This upgrade ensures full compliance with prevailing Australian electrical standards, thereby enhancing overall system reliability and occupant protection.

Enhanced Protection Against Overloads

Contemporary circuit breakers deliver precise overload protection by automatically disengaging at predetermined safe thresholds, a significant improvement over the less reliable ceramic fuses.

According to research conducted by the National Fire Protection Association (NFPA), these devices can reduce overload incidents by as much as 80%, thereby mitigating the risk of electrical fires, which contribute to more than 40,000 residential incidents in the United States each year.

In a standard household environment, circuit breakers enable the safe, concurrent operation of high-amperage appliances-such as clothes dryers requiring 30 amps, microwaves at 15 amps, and refrigerators-without the danger of electrical surges.

Constructed from robust thermoplastic materials, circuit breakers are engineered to endure more than 10,000 operational cycles, substantially outlasting traditional fuses, which are typically limited to one or two uses.

For optimal implementation, it is recommended to engage a licensed electrician to install Arc-Fault Circuit Interrupter (AFCI) and Ground-Fault Circuit Interrupter (GFCI) breakers in accordance with the 2023 National Electrical Code (NEC) standards. This configuration facilitates efficient resets directly from the electrical panel and represents a prudent investment, as it helps avert average fire damage costs exceeding $5,000 while promoting sustained home safety.

Integration of Residual Current Devices (RCDs)

The integration of Residual Current Devices (RCDs) facilitates the detection of leakage currents as low as 30mA, enabling the swift disconnection of power to mitigate electrical shocks and faults.

This rapid response is essential for maintaining safety, as illustrated in residential environments where an RCD has prevented a child from sustaining a fatal shock upon contacting a wet electrical outlet during play near a bathroom sink.

According to AS/NZS 3000:2018 standards, which mandate RCD installation for all final sub-circuits in new electrical systems, these devices can reduce electrocution risks by up to 95%, according to reports from SafeWork Australia.

To achieve effective integration, Type A RCDs should be installed at the main switchboard by a licensed electrician, with monthly testing performed by activating the ‘Test’ button. Such devices are particularly vital in modern homes incorporating solar panels or electric vehicle chargers, where they offer protection against heightened fault potentials in high-load configurations.

Overall Reduction in Fire Risks

Upgrades substantially mitigate fire risks by substituting hazardous components with compliant, fire-resistant alternatives in accordance with AS/NZS 61439 standards.

For example, the installation of arc-fault circuit interrupters (AFCIs) in switchboards enables the detection of electrical arcs, which account for approximately 60% of residential fires, based on data from Fire Brigades Australia. Consider a documented case from a 2022 storm in Queensland: In a home that had undergone upgrades, the AFCI activated to interrupt power during a lightning-induced fault, thereby averting a potential fire that could have resulted in total property loss.

To execute these upgrades, homeowners are advised to engage licensed electricians for a comprehensive assessment of electrical panels against AS/NZS 61439 criteria, with associated costs typically ranging from $500 to $2,000. Such measures not only diminish fire hazards but also generate significant insurance benefits, including potential annual savings of up to $10,000 through reduced premiums validated by compliance certification.

How Does Upgrading Align with Australian Electrical Standards?

Upgrading switchboards ensures strict compliance with rigorous Australian standards, such as AS/NZS 3000:2018, which mandate the integration of contemporary safety features to mitigate potential hazards.

Compliance with AS/NZS 3000 Wiring Rules

The AS/NZS 3000:2018 standard establishes comprehensive wiring rules that mandate switchboards to accommodate current loads and incorporate fault protection mechanisms. Consequently, upgrades are required for older installations that do not meet these criteria.

To achieve compliance, Residual Current Devices (RCDs) must be installed on all final sub-circuits, with placement at the switchboard and a sensitivity of 30mA to mitigate the risk of electrocution, in accordance with Clause 2.6. Suitable examples include Type II RCDs, which are designed for detecting DC faults in solar photovoltaic systems.

Circuit ratings must be aligned with calculated load requirements; for residential mains, a minimum capacity of 63A is necessary, complemented by Miniature Circuit Breakers (MCBs) rated at 16-20A for lighting circuits. In the context of solar panel integration, dedicated circuits compliant with AS/NZS 4777 are essential, with inverters connected through appropriate isolators to prevent overloads-typically utilizing 1.5mm cabling for systems up to 5kW.

The complete standard is available for purchase from Standards Australia (standards.org.au).

Failure to comply may result in substantial fines of up to $10,000, as demonstrated by enforcement actions during audits in Victoria last year.

Requirements for Modern Safety Features

Standards necessitate the inclusion of features such as residual current devices (RCDs) and surge protection within switchboards to accommodate contemporary electrical inputs, including generators and electric vehicle (EV) charging systems.

To ensure compliance with AS/NZS 61439, switchboard designs must integrate industry best practices for safety and system integration. Essential requirements encompass:

- RCDs for all circuits to mitigate the risk of electrical shocks and faults, particularly in scenarios involving high-load EV chargers.

- Clearly labeled circuit breakers to facilitate rapid identification during maintenance or emergency situations.

- Surge protection devices with a minimum rating of 20kA to protect against voltage spikes originating from generators.

- Compatibility with battery storage systems, enabling efficient DC-AC conversion without risk of overload.

A noteworthy case study involves a residential upgrade in Brisbane, where a compliant switchboard successfully incorporated Tesla Powerwall batteries and a solar photovoltaic array, resulting in complete energy independence. This configuration reduced reliance on the grid by 90%, according to data from Energy Queensland, with installation costs approximately AUD 5,000 and a return on investment achieved in less than seven years via feed-in tariffs.

Who Should Handle Your Switchboard Upgrade?

It is essential that switchboard upgrades be undertaken solely by licensed electricians to uphold safety standards and regulatory compliance, as stipulated by Australian authorities.

Role of Licensed Electricians

Licensed electricians conduct assessments, installations, and certifications for electrical upgrades, ensuring compliance with AS/NZS 3000:2018 standards and mitigating risks such as improper wiring.

To perform a safe upgrade, adhere to the following three-step process:

- Site Audit: Conduct an inspection of the existing electrical setup to identify potential hazards, such as ceramic fuses that may overheat and cause fires-prevalent in homes constructed before the 1980s, as reported by Energy Safety Victoria.

- Design Compliant Switchboard: Develop a layout incorporating components approved under AS/NZS 3000:2018, including Type A Residual Current Devices (RCDs) for residual current protection and surge arrestors capable of handling loads up to 63A.

- Install and Test: Securely mount the new switchboard using torque wrenches to ensure reliable connections, followed by insulation resistance testing with a Megger instrument.

The entire process typically requires 4 to 6 hours. It is essential to avoid engaging unlicensed personnel, as this may invalidate insurance coverage and incur fines of up to $110,000 under Australian regulations.

Steps to Select a Qualified Professional

Selecting a qualified electrician necessitates verifying licenses, reviewing testimonials, and obtaining quotations from reputable firms, such as Dawson Electric in Queensland.

- Commence by confirming the possession of an A-grade electrical license through the Electrical Safety Office (ESO) in Queensland, thereby ensuring conformity with the Electrical Safety Act 2002 and mitigating the risk of fines up to $1,500 for uncertified electrical work.

- Subsequently, assess previous projects; for example, evaluate firms like M.E. Ward in Brisbane, which maintains a 4.8-star Google rating derived from more than 200 reviews.

- Next, solicit a complimentary power usage audit; instruments such as the ESO’s online estimator can facilitate the identification of potential efficiency enhancements.

- Finally, compare at least three quotations, verifying the inclusion of requisite compliance certificates.

This procedure typically requires 1 to 2 days and upholds the safety and integrity of your residence.

What to Expect During the Upgrade Process?

The switchboard upgrade process is managed by a licensed electrician and encompasses a comprehensive assessment, the safe disconnection of existing systems, and the installation of state-of-the-art components to enhance overall safety and reliability.

Initial Inspection and Assessment

The procedure commences with a comprehensive inspection, during which the electrician assesses the switchboard for indicators such as ceramic fuses and audible buzzing, typically conducted through a complimentary audit.

- Subsequently, perform a visual examination for signs of overload, including frayed wires or hot spots, which requires approximately 30 minutes.

- Proceed with load testing utilizing a multimeter to measure the current draw, ensuring it remains below 80% of capacity in accordance with the AS/NZS 3000:2018 standards, which stipulate safe wiring practices in Australia and New Zealand.

- Prepare a risk assessment report that outlines the findings and any compliance discrepancies.

- Furnish a quotation for necessary upgrades, such as the installation of RCBOs for enhanced fault protection.

The entire process typically takes approximately one hour. It is advisable to avoid the common error of omitting testing, as this may result in incomplete upgrades and potential safety risks, in accordance with the guidelines of the Electrical Safety Office.

Installation of New Circuit Breakers

The installation process requires the safe disconnection of power sources, the removal of existing fuses, and the installation of new circuit breakers and residual current devices (RCDs) customized to the specific requirements of residential circuits.

To proceed methodically and ensure compliance with safety protocols:

- Power Isolation for Safety: Begin by isolating the power supply, including switching off the main circuit breaker and verifying the absence of voltage with a calibrated digital multimeter, such as the Fluke 117. This step must adhere to the National Electrical Code (NEC) standards for residential electrical installations.

- Mounting the Distribution Board: Install a new distribution board, for example, a 24-way consumer unit from reputable manufacturers like Hager or Wylex, by securely affixing it to a robust wall-mounted bracket.

- Wiring Individual Breakers: Connect the appropriate breakers for various loads, such as a 16A miniature circuit breaker (MCB) for ovens or a 32A residual current breaker with overcurrent protection (RCBO) for solar inverters. Utilize color-coded wiring conventions: brown for live conductors, blue for neutral, and green/yellow for earth/ground.

- System Testing: Validate the installation using a load simulator to assess for unintended tripping, by applying a simulated overload of 10-20%.

- Completion and Compliance: The entire procedure typically requires 3-5 hours. It is imperative to engage a licensed electrician to ensure adherence to applicable local regulations, such as the UK’s BS 7671 standards, and to prevent post-installation overloads that may invalidate manufacturer warranties.